Improper operation of the timing belt during installation often causes premature damage to the timing belt or early failure during use. The cost of the timing belt has been greatly increased, and the editor has sorted out several common wrong installation situations!

walk the inner circle

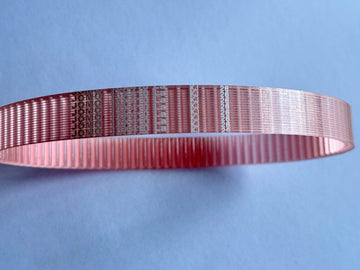

►The fit between the shaft and the inner hole of the synchronous belt is too loose (commonly known as "inner ring")

Because the fit between the shaft and the inner hole is too loose, sliding occurs between the shaft and the inner hole surface. Sliding friction will cause heat, which will damage the timing belt due to heat.

Slip marks between shaft and bore surface

►Friction between the end face of the inner ring and the shaft shoulder generates cracks.

When the inner ring is "walking", the sliding friction between the inner ring and the shaft will generate high temperature. Because the contact surface between the end face of the inner ring and the shaft shoulder is small, the temperature will be higher. Thermal cracks are generated on the end face of the inner ring, and the continuous extension of the thermal cracks will cause the inner ring of the synchronous belt to break during use.

►Adhesion occurs between the shaft and the surface of the inner hole

due to the "walking inner ring" that causes sliding friction between the inner hole and the surface of the shaft, and the high temperature causes the surface metal to melt and cause adhesion

walk the outer circle

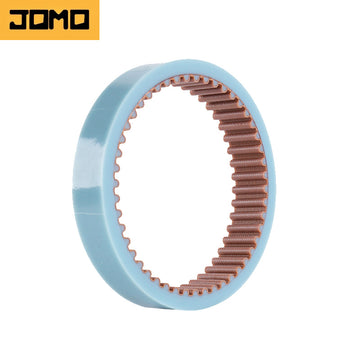

►The matching between the housing aperture and the outer diameter of the synchronous belt is too loose (commonly known as "outer ring")

Because the matching between the housing aperture and the outer diameter of the synchronous belt is too loose, sliding occurs between their surfaces. Sliding friction will cause heat, which will cause the synchronous belt to heat up and be damaged. Hit the synchronous belt directly with a hammer to install the synchronous belt with an interference fit of the inner ring (or outer ring). It is forbidden to directly hit the end face of the inner ring (or outer ring) of the synchronous belt with a hammer, as it is easy to break the rib. The sleeve should be placed on the end face of the inner ring (or outer ring), and the sleeve should be tapped with a hammer to install.

The installation force is transmitted through the rolling elements.

When installing a timing belt with an interference fit of the inner ring, the force cannot be transmitted to the inner ring through the outer ring and the rolling elements. This will damage the synchronous belt raceway and the surface of the rolling elements, causing the synchronous belt to generate noise during operation and be damaged in advance. The correct method should be to use the sleeve to directly act on the end face of the inner ring

The heating temperature is too high.

Some users heat the inner hole of the timing belt with an acetylene spray gun. When the heating temperature exceeds 727°C (the phase transition temperature of the timing belt steel), the metallographic structure inside the timing belt steel will change. When the timing belt is cooled, the inner hole of the timing belt cannot return to its original size, which is usually larger than that before heating.

After being heated by the acetylene spray gun, the surface of the synchronous belt turns black. If the installation is not in place, one side of the synchronous belt is stressed. Self-aligning rollers. Ring side raceway and one row of rollers damaged

The installation method of the synchronous belt is a problem that is often encountered in the use of the synchronous belt, and it is also a problem that is often difficult and troublesome. Only by mastering the scientific and correct installation method can the synchronous belt be used normally and the service life of the synchronous belt can be extended.